Our employees are not only highly motivated but also highly qualified. The following list gives you an exact overview of the scope and details of our range of services.

Project Management

To ensure that your new system gets up and running as quickly as possible, we assume responsibility for your project right from the start and work with you to find the most suitable installation and service model. We put together the right team and coordinate the various technical crews in accordance with your schedule. The following services ensure that all of our projects run smoothly:

- Detailed needs analysis and service strategy

- Assembly and deadline planning

- Capacity and resource planning

- Coordination of all operations

- Cost and progress control

Servicing

One thing is certain: regular servicing is always cheaper than a sudden system failure. We work with you to develop efficient service models and guarantee timely completion and documentation. And our services constantly evolve with your technical requirements. We offer the following services:

- Regular and preventive maintenance

- Customized service and maintenance contracts

- Troubleshooting and analysis

- Complete overhauls and repairs

- Retrofitting

- Logistics consulting

- Customer and quality management

Mechanical Systems

Our experienced technicians are well prepared for every task. They bring their own tool box and company-owned, high-performance measuring equipment with them and carry out each assignment independently according to the specifications. They speak the language of your machines fluently – be it mechanics or electropneumatics – and perform the following:

- Assembly of individual parts and complex assemblies on the basis of parts lists and drawings

- Final inspections and commissioning of systems’ mechanical and pneumatic processes

- Setting up and adjusting of assemblies

- Quality inspections and compilation of corresponding documentation (e.g., acceptance book)

- Assurance of required quality standard

- Independent assembly of complex machines and equipment

- Process optimization

Electrical Systems

Our electrical experts can quickly and thoroughly familiarize themselves with any circuit diagram. They take care of the electrical installation of your machines and systems and wire them according to the existing electrical diagrams. They can also take care of the assembly and the wiring of the associated control cabinets at the same time. In addition, they can handle the following tasks:

- Monitoring of preliminary and final inspections

- Testing and error analyses

- Independent installation of complex machines and equipment

- Independent testing of electrical systems in accordance with applicable standards

- Final inspection and commissioning of machines and systems

- Process optimization

Assembly Outsourcing

To prevent you from losing unnecessary time when setting up your machines and systems, you can outsource part of the assembly process to us. We first preassemble the planned system as far as possible at our facility and then complete assembly at its final installation site. This ensures that your production process can run without interruption for as long as possible and can quickly resume after a brief conversion phase. To achieve this, we offer the following:

- Consultation and planning services for assembly outsourcing

- Scheduling and process planning

- Selection and assembly of suitable structures

- Preassembly in buildings provided by us

- Planning and execution of the shipment of preassembled machine and system components

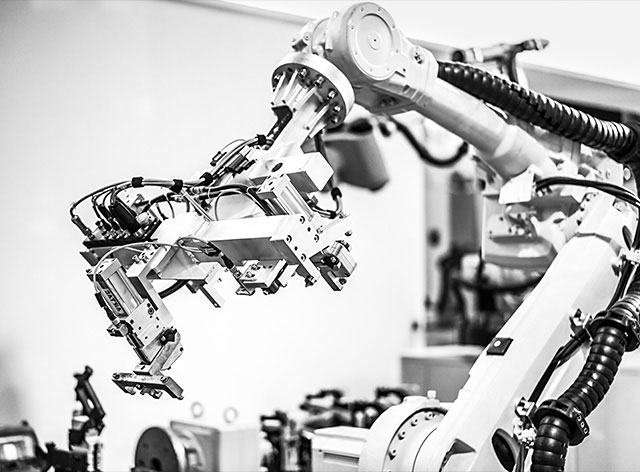

Robotics

We also have our trained specialists available to program your robots. They are proficient in communicating with machines using all of the common programming methods and are familiar with the interfaces and parameters required to program your software so that the production process can resume quickly. We offer the following:

- Programming, final inspection, and commissioning of robots

- Specialists trained for KUKA, Fanuc, and ABB robots

- Final inspection and commissioning – online and offline

- Performing of simulations

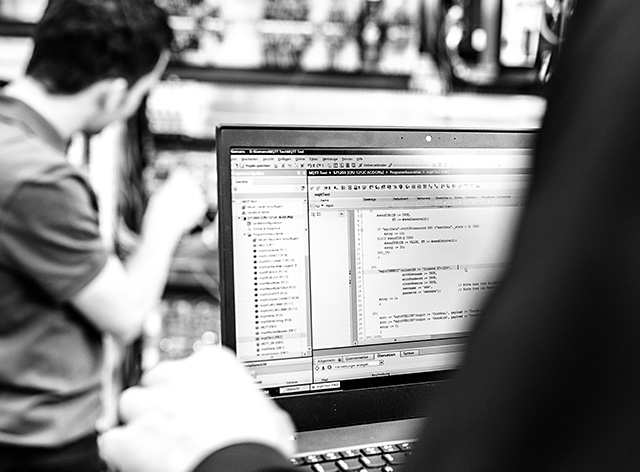

PLC

Our specialists for programmable logic controllers independently develop the required custom software applications for your systems. They plan and create complete control concepts and ensure that they are implemented correctly. These are our services in detail:

- PLC for Siemens, Beckhoff, Rockwell, and Allen Bradley

- Automatic and calibration functions

- Collision avoidance and product tracking

- Verification and acceptance of automation solutions

- Optimization of operational sequences and processes

- Documentation and progress monitoring

3-D Metrology

To really be able to complete all the work involved in systems engineering, we have the latest 3-D metrology solutions in our portfolio. For example, our technicians work with the FARO® Laser Tracker Vantage (0.049 mm volumetric accuracy to 10 m, 110 m3 measuring volume). The result is maximum precision, perfect coordination of the different disciplines, and uniform quality standards. Our metrologists offer the following services:

- Documenting of the current situation

- Defining and labeling of all the measuring points

- Assistance with disassembly/retooling

- Surveying of the layout

- Support with positioning the maschine

- Set-up of the required condition, adjustment of assemblies and installations

- Final inspection and commissioning

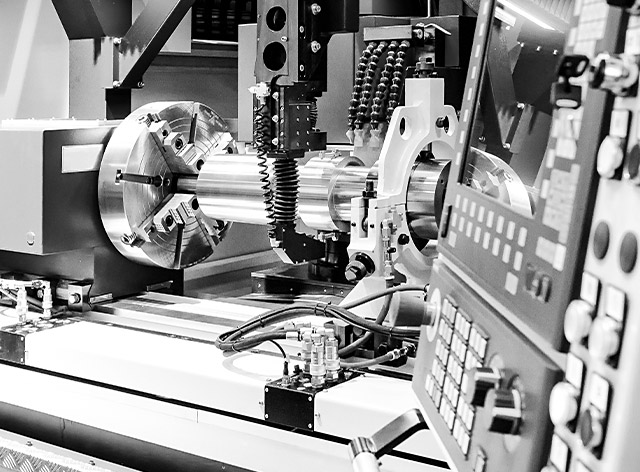

CNC Grinding Machines

Our employees are specialized in commissioning and servicing CNC grinding machines. In addition, we eliminate and analyze errors, replace components, and have expert process optimization specialists on our team. Our services include the following:

- Assembly and disassembly of mechanical, hydraulic, and pneumatic machines and components

- Finalization of machines and machine systems according to specifications

- Retooling, retrofitting, overhauling of CNC systems as well as PLC-controlled systems with multiple or complex control loops

- Inspection and redefining of machine geometry

- Technical commissioning and application commissioning

- Functional testing, error diagnostics, and troubleshooting

- Process support and process analyses

- Preparation, monitoring and carrying out of preliminary and final acceptance tests

- On-call service, customer service, maintenance, and repairs

- Training for customers and operators

Mehnert makes it easy to understand.

Watch an Animation to Get an Overview of Our Services.